Together with Protech Sticky Solar Power build and tested back contact solar cell modules connected with the tape solution.

Mini modules was fabricated with The Tape Solution at Sticky Solar Power and tested at Protech together with Dr. Juras Ulbikas, Algirdas Balezentis at The Applied Research Institute for Prospective Technologies in Vilnius Protech.

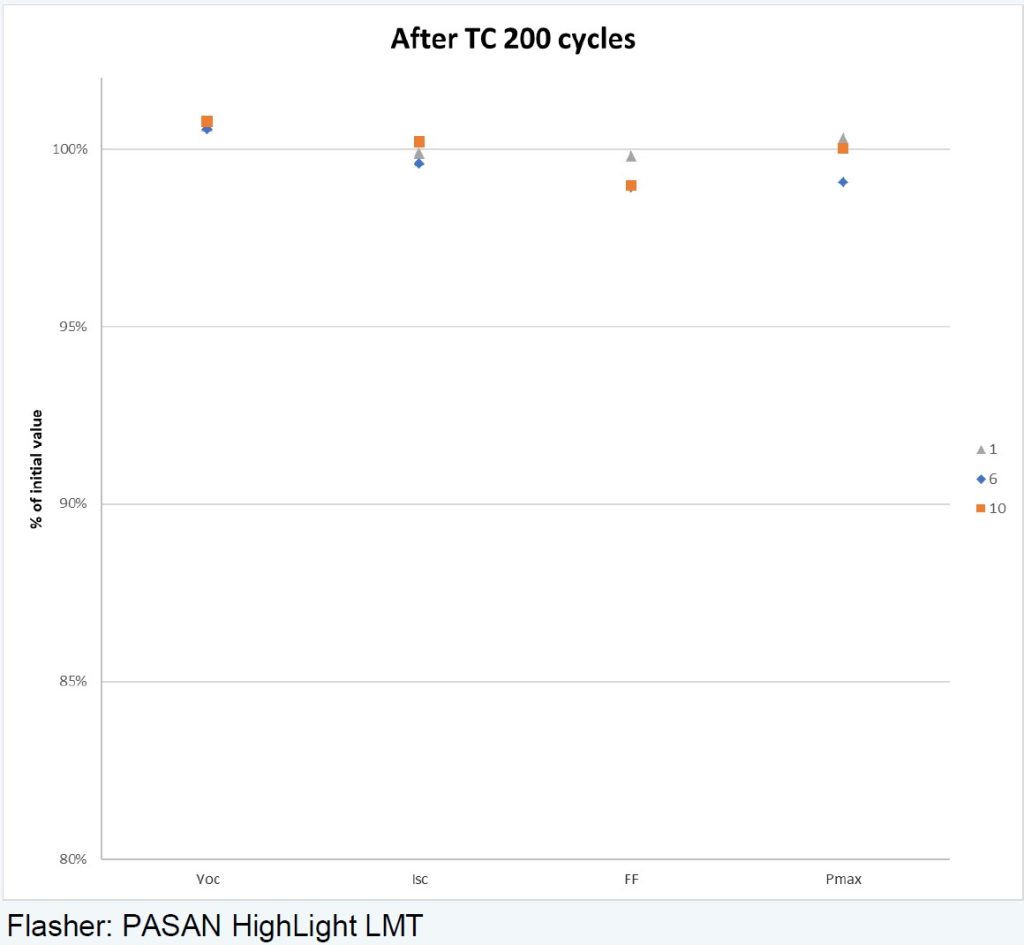

Tests was conducted according to the IEC 61215 standard with UV exposure of 15 kWh, Thermal cycling 200 cycles (+85 to -40°C) and Damp heat 1000 hours (+85°C at 85 % RH) within the limit of -5% degradation of Pmax. Test was conducted on ½ cut M6 Zebra cells with 6BB from ISC Konstanz.

The results was presented at the back contact workshop in Hameln . Below we show the results from 3 modules tested for TC 200 cycles.

The modules connected with the tape solution was also tested for Damp Heat 1000 hours (DH 1000). The results is shown below:

Test was conducted on modules containing of ½ cut M6 Zebra cells with 6BB from ISC Konstanz

The Tape Solution™ revolutionizes solar photovoltaic module manufacturing by enabling substantially higher throughput at lower cost, more ambitious levels of sustainability and minimized factory footprint.